Services

-

Baler Repair

Professional baler repair for all major brands including hydraulic rebuilds and electrical diagnostics. Emergency service available 24/7 across Florida.

-

Industrial Controls

PLC programming, HMI repair, and control panel troubleshooting. Expert diagnosis and reliable repairs for automated systems.

-

Hydraulic Repair

Emergency hydraulic hose replacement, cylinder rebuilds, and pump repair. Mobile units provide immediate on-site service throughout Florida.

-

Shear Repair

Industrial shear repair including hydraulic systems and blade replacement. Emergency service for metal fabrication and recycling equipment.

-

Shredder Repair

Complete shredder repair and maintenance services. Emergency breakdowns, blade replacement, and preventive maintenance programs available.

-

Compactor Repair

Industrial compactor repair with same-day emergency response across Florida. We service all compactor types with mobile repair units.

-

Variable Frequency Drive Repair

Variable frequency drive repair and programming services. Fast diagnosis and replacement for all major VFD brands and models.

-

Power Press Repair

Power press repair, clutch rebuilds, and safety system inspections. Emergency service for stamping and forming equipment across Florida.

-

Mobile Hose Repair

Mobile hose repair and on-site hydraulic hose replacement. Emergency hose repair service and industrial hose maintenance

-

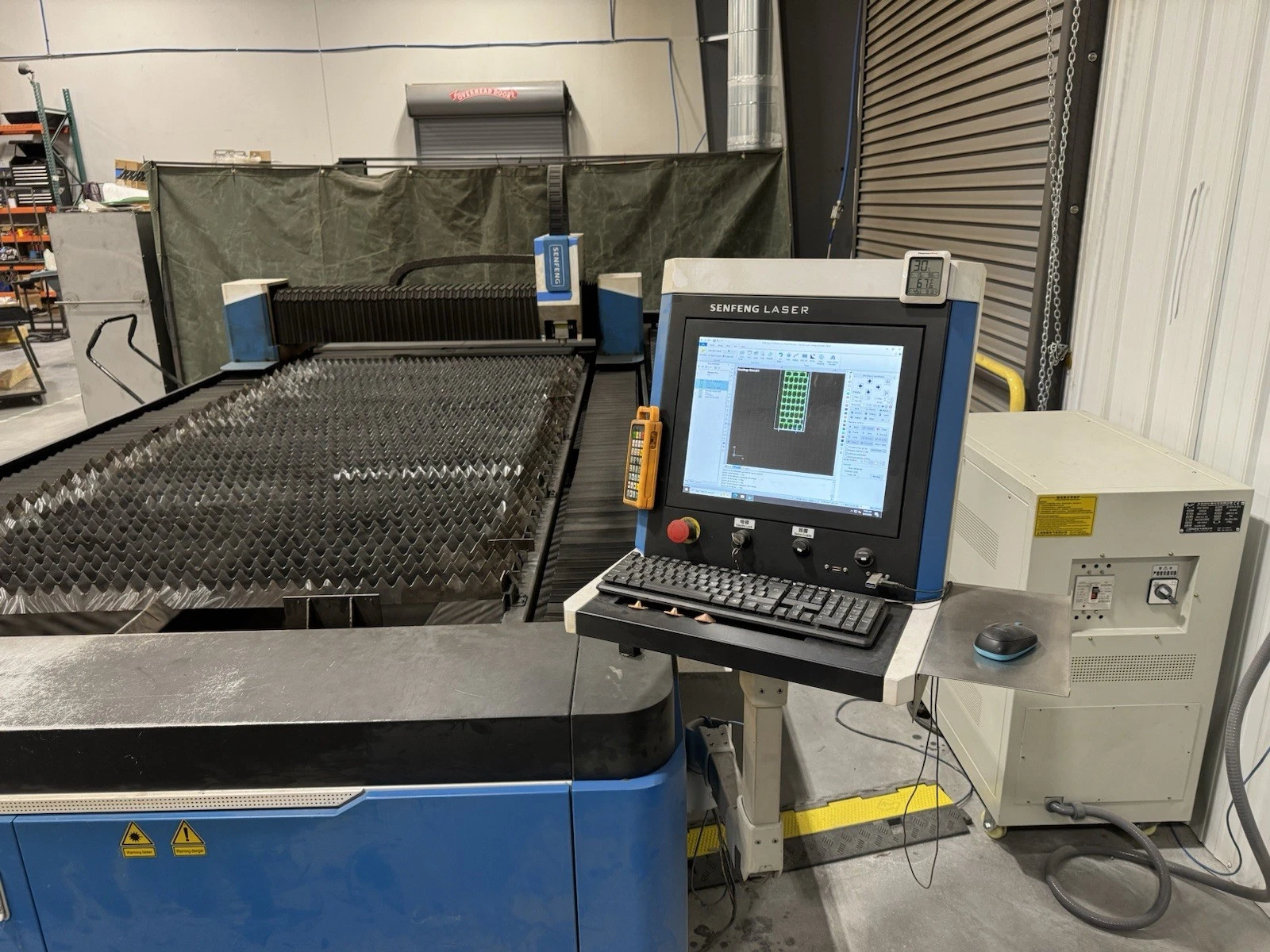

Laser Cutter Repair

Laser repair and component replacement for all major brand’s laser systems. Emergency service available 24/7 across Florida.

Service Areas

We provides expert mobile industrial repair and maintenance solutions for businesses across Northern Florida, including Jacksonville, Gainesville, Tallahassee, Ocala, and surrounding areas. Our skilled technicians deliver on-site equipment repairs, preventive maintenance, and emergency industrial services that minimize downtime and keep your operations running efficiently. Northern Florida businesses rely on MGI Florida's prompt mobile repair services and experienced team to maintain peak operational performance when and where you need it most.